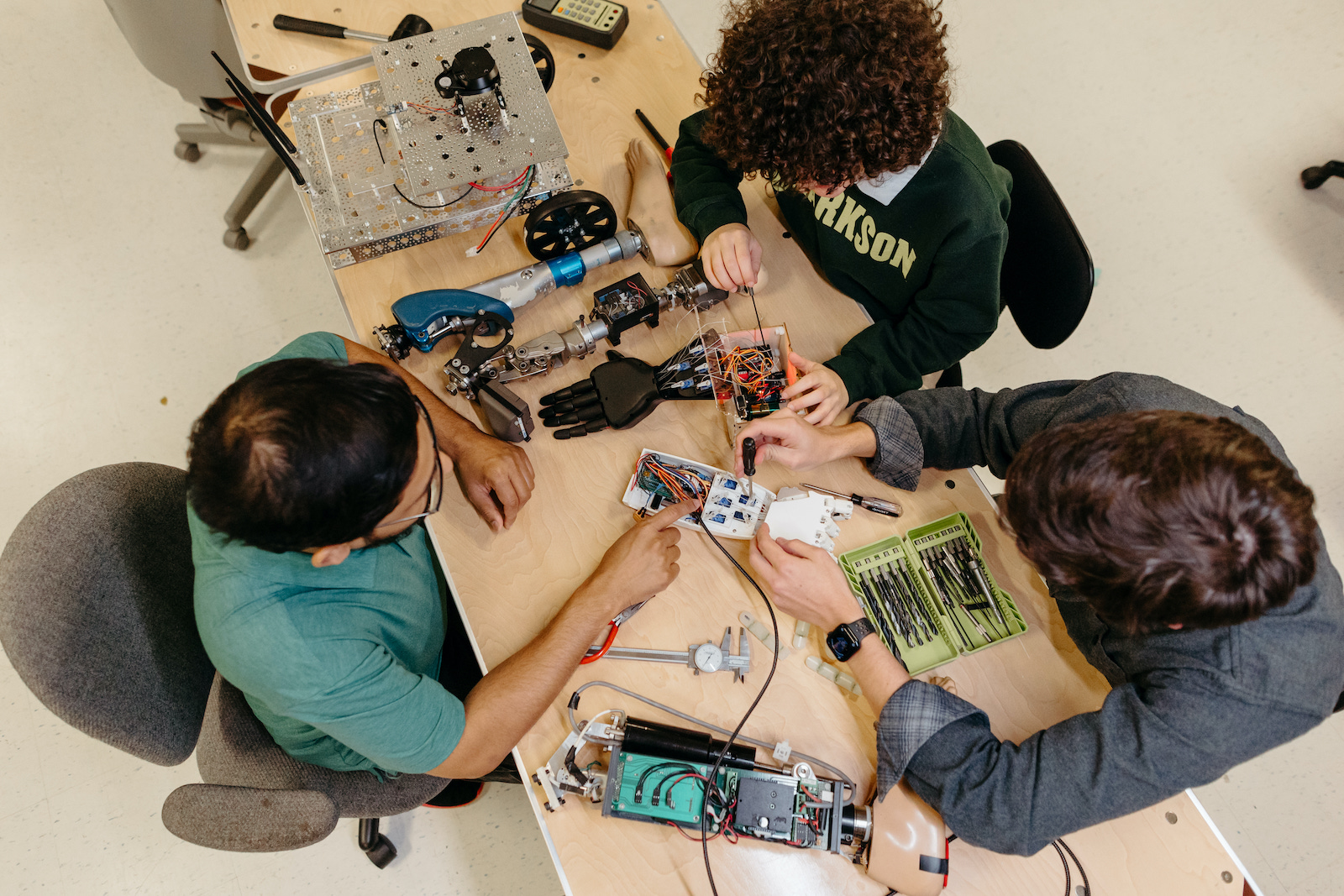

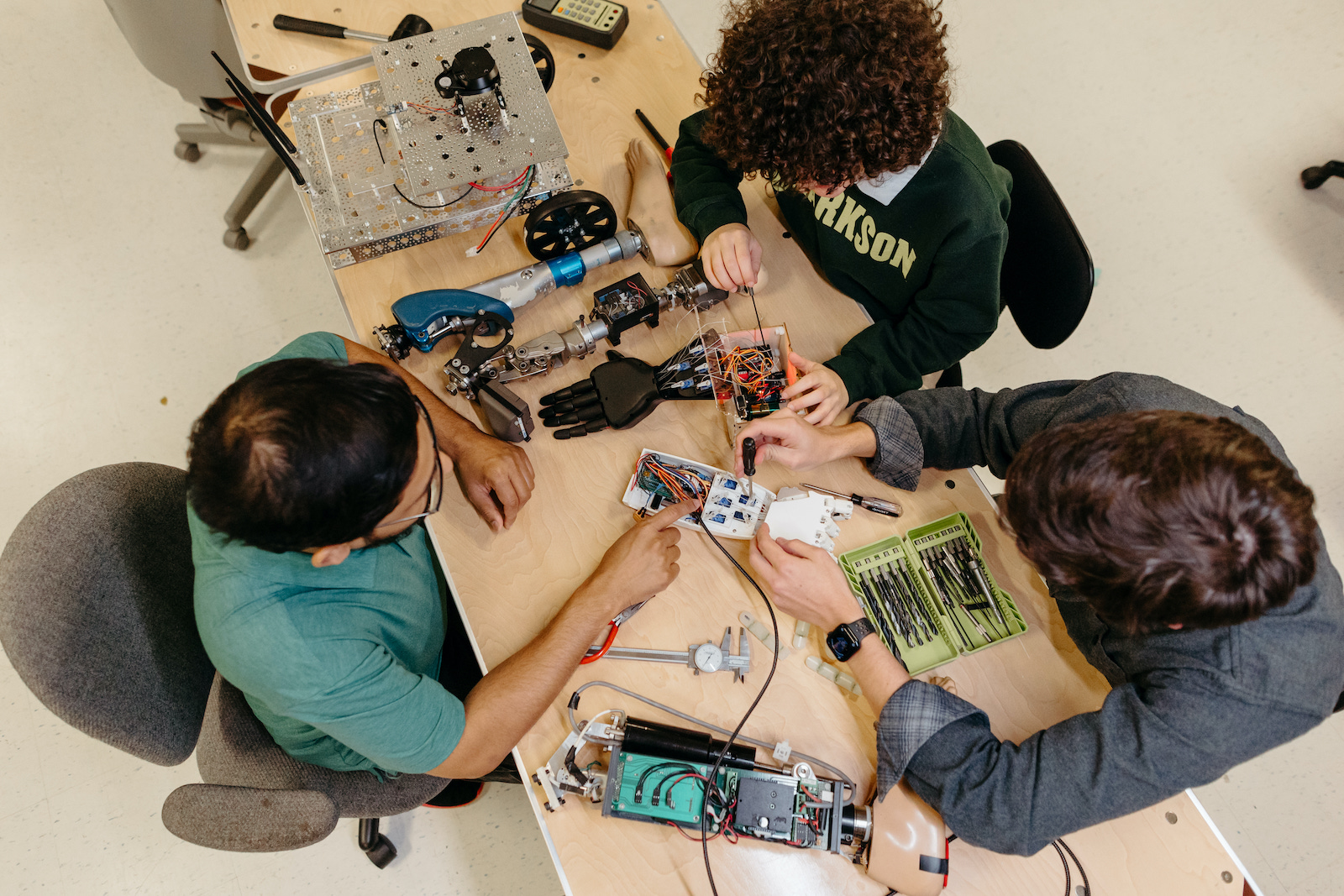

Research and Innovation

Faculty Expertise

Clarkson has a deep bench of faculty expertise in semiconductor-related areas such as chemical mechanical planarization, chip design, manufacturing processes, contaminant treatment, and system integration.

Dr. Goodarz Ahmadi: Focuses on fluid dynamics and particle transport, providing insights into system designs that address contamination spread and control in semiconductor manufacturing and environmental systems.

Dr. Daryush Aidun: Specializes in manufacturing and welding processes, contributing to advancements in semiconductor fabrication techniques.

Dr. Silvana Andreescu: Develops advanced sensing platforms for the detection of environmental pollutants, including heavy metals and PFAS, enhancing monitoring capabilities crucial for EPA monitoring, environmental protection and public health.

Dr. Prashant Athavale: Applies interdisciplinary research in the areas of variational analysis, data science, and applications to image processing for removal of noise from data and completion of the given data if some of the information is either noisy and/or missing.

Philip Barker: Distance Power Engineering MS Program Coordinator. Power Engineer specializing in electric power distribution, power quality, power system transients and inverter based resource interconnection.

Dr. Cetin Cetinkaya: Specializes in mechanics and photonics, with applications in non-destructive evaluation of semiconductor materials and structures, and the adhesion and removal of nano/micro-particles on wafers and photomasks.

Dr. Michelle Crimi: Focuses on developing novel approaches for treating recalcitrant compounds, including per- and polyfluoroalkyl substances (PFAS), and implementing these technologies more efficiently.

Dr. David Crouse: Focuses on microelectronics and photonics, contributing to the design and development of semiconductor devices.

Dr. Suresh Dhaniyala: Specializes in aerosol science, studying particle behavior that impacts air quality and contamination control in semiconductor environments.

Dr. Maria Gracheva: Pursues translocation dynamics of nanoparticles permeating through the nanopore in an n-Si semiconductor membrane, with the use of Brownian Dynamics to describe the motion of the charged nanoparticles in the self-consistent membrane electrolyte electrostatic potential.

Dr. Brian Helenbrook: Contributes to advanced computational modeling, aiding in the design and optimization of semiconductor devices and manufacturing processes.

Dr. Tom Holsen: Engages in research focused on the detection, fate, and remediation of environmental contaminants, including PFAS, contributing to the development of effective strategies for prevention and environmental cleanup.

Dr. Leo Jiang: Expertise in enhancing grid flexibility to accelerate decarbonization, grid reliability and resilience, situational awareness of power distribution systems, and interdependent critical infrastructures.

Dr. Taeyoung Kim: Addresses the design and control of semiconductor electrodeposition of interconnects, via-filling, and magnetic components into patterned wafers, corrosion inhibition of CMP, understanding of electrocatalytic materials, and electrochemical wastewater treatment. Plating with different waveforms (i.e., DC, pulse, pulse-reverse), bulk elemental analysis with XRF, surface characterization with SEM/TEM, molecular simulations, and designing electroremediation systems.

Dr. Melissa King: Focuses on the development of optically active nanomaterials for environmental application such as remediation and recycling of industrial byproducts.

Dr. Sitaraman Krishnan: Conducts comprehensive investigations into the chemical, mechanical, electrical, and thermal characteristics of polymer composites, ion transport phenomena in lithium-ion battery electrolytes, electrokinetic behaviors in chemical mechanical planarization.

Dr. Chen Liu: Computer architecture and microprocessor design, with expertise throughout the hardware/software stack, including hardware acceleration, energy-/power-aware computing, heterogeneous computing, high-performance computing, security, with key projects in autonomous vehicle technology innovation.

Dr. Xiaocun Lu: Focuses on functionalized mesoscopic structures, such as supramolecular architectures, colloid particles, and shear-thickening fluids, with the incorporation of contact-initiated polymerization (CIP) techniques and aggregation-induced emission (AIE) attributes for the development of next-generation stimuli-responsive materials with autonomous functions.

Dr. Marcias Martinez: Performs research on the development of a Holistic Structural Integrity Process for aerospace structures.

Dr. Ioannis Mastorakos: Focuses on the mechanical properties and applications of nanoscale composite nano foams, and on the deformation behavior of High Entropy Alloys.

Dr. Selma Mededovic: Specializes in plasma-based technologies for the degradation of persistent organic pollutants, such as PFAS, advancing innovative methods for water treatment and environmental remediation.

Dr. John Milne: As a former IBM executive, engages in extending operations research methodologies to address complex decision problems in supply chain management, planning, and scheduling, which are critical for the efficient production and distribution in the semiconductor industry.

Dr. Thomas Ortmeyer: Specializing in power quality, grid integration of power electronic converter, and dynamic performance of the power grid.

Dr. Elizabeth Podlaha-Murphy: Contributes to knowledge based in electrodeposition and electrochemistry, forwarding research on the understanding of kinetic-transport phenomena inherent to plating, creating more environmentally friendly electrodeposition processes, and in generating novel nanoscale structures of alloys and metal matrix composites for components in micro- and nano-size devices.

Dr. Alan Rossner: Using a streamlined lifecycle assessment to evaluate greenhouse gas emissions, the water footprint, human & aquatic toxicity, and eutrophication potential of CMP slurries to facilitate slurry selection from a sustainability perspective.

Dr. Dipankar Roy: Specializes on various materials aspects of electrochemical energy storage/conversion and semiconductor device fabrication.

Dr. Jihoon Seo: Focuses on the design of Chemical Mechanical Planarization (CMP) slurries and conducts fundamental research on CMP and post-CMP cleaning processes, essential for semiconductor manufacturing.

Dr. Richard Partch: Engages in research on nanoparticle synthesis and surface modification, which are critical for applications in semiconductor technology and pollutant removal.

Dr. Devon Shipp: Focuses on polymer chemistry, contributing to the development of advanced materials used in semiconductor manufacturing and environmental remediation.

Dr. Yang Yang: Leads research in developing innovative, non-thermal, cost-effective methods for PFAS remediation, such as the ultraviolet/sulfite–electrochemical oxidation process and mechanochemical ball milling achieving near-complete defluorination of PFAS in various wastewaters and solid wastes.

Dr. Jianhua Zhang: Expertise in behavior of cyber-physical power and energy systems, integrating power and data information systems, and hardware in the loop simulation.

Relevant Labs and Centers

CAMP has been designated as a New York State Center of Advanced Technology (CAT) since 1987 and dedicated to innovative research in materials processing and collaborates closely with industry partners to translate technological advancements into practical applications. CAMP and its faculty group are globally known for their work in the semiconductor industry, particularly around chemical mechanical polishing (CMP) as well as PFAS remediation. It supports companies interested in understanding and exploiting state-of-the-art, advanced, tailor-designed materials and processes to improve their products, solve manufacturing challenges, increase yield, lower costs and foster innovation.

The Clarkson - SUNY ESF Center of Excellence in Healthy Water Solutions is funded by New York State through NYSTAR, municipal projects and companies that need synergistic problem-solving on the wide range of water issues impacting New York State and beyond.

Center for Air and Aquatic Resources Engineering & Sciences (CAARES) is a world-leading analytical facility for the detection of PFAS compounds and other contaminants that have historically been in manufacturing processes. It is an accredited DoD ELAP lab for EPA Method 1633 PFAS analysis in water.

NSF IUCRC Center for Electric, Connected and Autonomous Technologies for Mobility (eCAT) focuses on developing and deploying next-generation electrification, resilient sensing/perception, real-time edge computing, and smart infrastructure techniques to achieve higher safety and efficiency, aiming to initiate and accelerate the transformation of mobility methods from conventional vehicles to electric, connected and autonomous vehicles by creating essential and innovative technologies. At eCAT center, we believe semiconductor and computing will play a huge role for the future of the automotive industry. Dr. Chen Liu is the director of the eCAT center at Clarkson University.

The CMP Laboratory (PI: Jihoon Seo) has a CMP wafer polisher for 50 mm, 150 mm, and 200 mm wafer sizes, two coupon polishers, a post-CMP cleaner for 200 mm wafers, two automatic thickness measurement tools for 200 mm wafers, two potentiostats, a surface profiler, a 3D measurement system, atomic force microscopy (AFM) for 200 mm wafers, 3D printing capabilities, a dynamic light scattering (DLS) particle sizer, and a large particle counter.

The Aerospace Testing and Life Assessment Systems (ATLAS) Laboratory is part of CAMP's instrumental facilities established to address the many characterization needs of research projects happening across Clarkson University's Campus and New York State businesses. With a focus on material properties, CAMP specializes in microscopy (SEM, TEM, AFM), microanalysis (EDS, XRF, XRD), and thermal analytics (DMA, TGA, DSC), and mechanical properties through the newly installed Aerospace Testing and Life Assessment Systems (ATLAS) Laboratory. Many of these high-end tools are fitted with peripheral attachments to perform measurements under different environments with the capability to control atmosphere and temperature. By leveraging faculty demand the CAMP is constantly changing and upgrading instrumentation to better refine the characterization technologies being offered. Thorough training, analytical expertise, and our knowledgeable technical staff provide analytical solutions to a wide range of material-related problems.

The Krishnan Surface and Interfacial Engineering Lab (PI Sita Krishnan) at Clarkson University specializes in surface and thin film engineering for semiconductor processing and advanced materials. A core focus is chemical mechanical planarization (CMP), where the lab develops next-generation slurries with low defectivity, high removal rates, and enhanced material selectivity. In collaboration with Samsung Electronics and Mosaic Microsystems, the lab optimizes CMP processes, including post-CMP cleaning and Through-Glass Via planarization. Their work with BASF has advanced latex-based CMP slurries for minimal surface defects. With expertise in thin film processing, surface metrology, nanoindentation, adhesion/friction behavior, rheology, and molecular simulations, the lab engineers materials with tailored mechanical, thermal, and electrochemical properties.

The Photoacoustics Research Lab (PI: Çetinkaya) at Clarkson University specializes in semiconductor manufacturing research, focusing on materials characterization using pulsed laser and ultrasonic methods, nanoparticle adhesion and removal, and ultrasonic thin film characterization. The lab is equipped with a pulsed laser system, Polytec vibrometer, Laser Doppler Velocimetry (LDV), pulser-receiver, and an air-coupled ultrasonic measurement system for non-contact diagnostics.