Center for Advanced Materials Processing (CAMP)

Recognized Areas of Excellence in Use-Inspired R&D...

Holistic Materials Characterization for the Building, Aerospace & Defense Industries

Nanomaterials, colloids, and surface science for the sensor, healthcare, and environmental care industries

...Leveraging Our Research Strengths

Materials Synthesis

- Fine particle synthesis, surface modifications and dispersions.

- Thin and thick film coatings.

- Smart materials.

- Functional polymer materials.

- Materials and structures for energy conservation and solar devices.

- Biocompatible materials.

Materials – Computational Methods

- Models and simulations for fine particle dispersions in air and/or fluids.

- Finite element analysis (FEA) of structural materials.

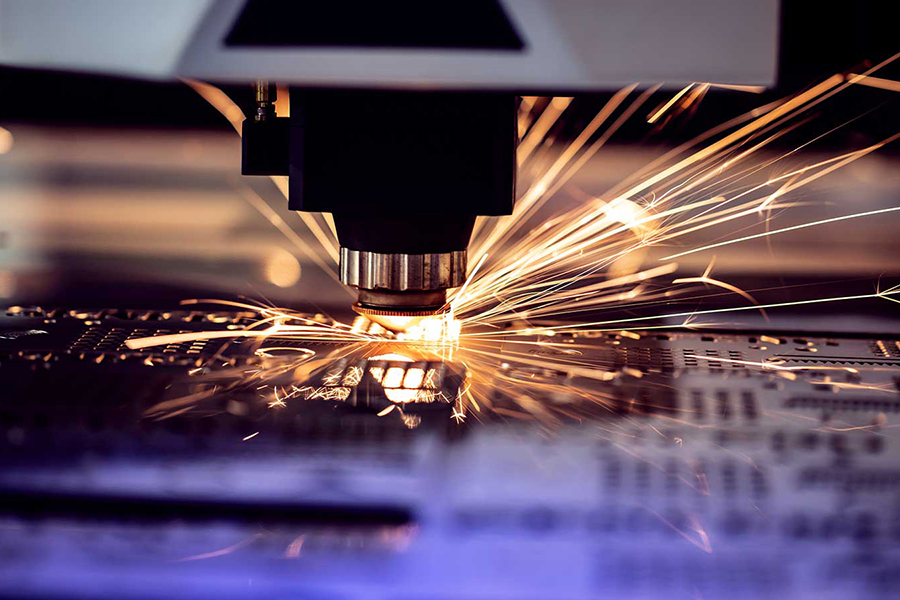

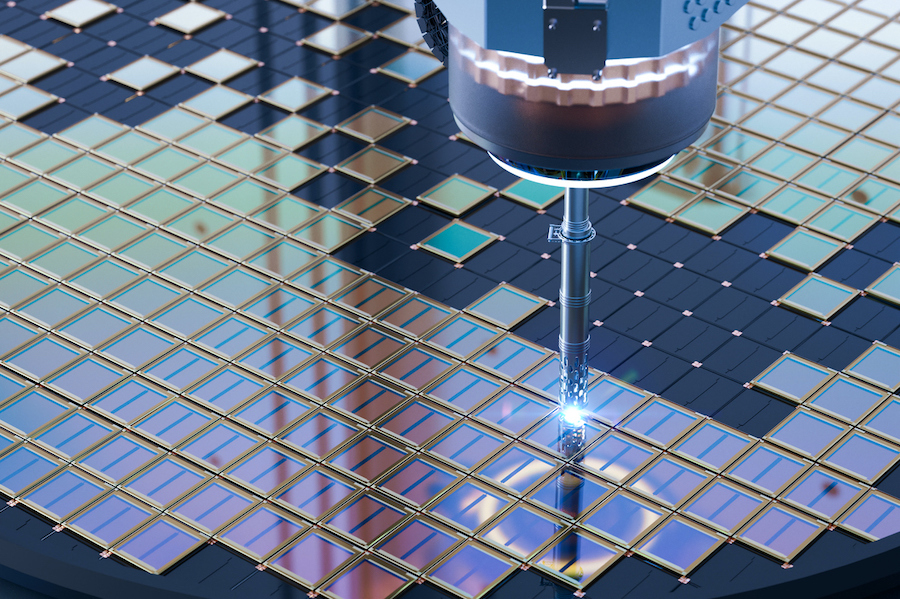

Materials Processing

- Additive manufacturing using metals and alloys.

- Film deposition methods for metals, alloys and dielectrics.

- Anti-corrosion technology.

- Chemical mechanical polishing.

Materials Characterization

- A full spectrum of analytical tools including electron microscopy (SEM, TEM), atomic force microscopy (AFM), powder X-ray diffraction, single crystal X-ray crystallography and a range of thermal and mechanical analysis instruments.

Contact us

Learn more about the benefits of research collaborations through CAMP.

350 CAMP Building

Box 5665

8 Clarkson Avenue

Potsdam, NY 13699

Phone: 315-268-2336

Fax: 315-268-7615

Email: camp@clarkson.edu

The Center for Advanced Materials Processing at Clarkson University is an NYSTAR-designated Center for Advanced Technology.

Inside CAMP

View CAMP's Facilities and Instrumentation

Hear from Devon Shipp, the Director of the Center for Advanced Materials Processing, and take a brief tour of the CAMP facilities.

Working Arrangements

We offer a variety of contractual arrangements to meet corporate needs and expectations:

- Master Collaboration Agreement (MCA) to accommodate multiple research areas and to facilitate long-term relationships.

- Analytical Service Agreements (ASA) for material analysis and testing.

- Tailored agreements for workforce development, including internships, visiting scientists, co-ops and more.

Companies typically engage in initial discussions regarding their needs and the potential for CAMP to assist them. Connections with faculty can be made via CAMP staff or directly with faculty members themselves.

Clarkson is committed to working closely with companies to capitalize on emerging technology and innovations. We do this through licensing patents and technologies, collaborating with industrial partners and incubating startups through the Shipley Center for Innovation.

CAMP'S IMPACT

NYSTAR Designation

CAMP has earned the Empire State Development's Division of Science, Technology and Innovation's (NYSTAR) designation as a Center for Advanced Technology (CAT) since 1987, with four successful performance-based contract renewals with New York State. CAMP was redesignated a CAT in 2018 for an additional 10 years.

Economic Development

CAMP champions economic development in northern New York, across New York State and beyond through partnerships with economic development organizations, industry, innovation centers and research institutes.

Job Creation

CAMP has helped companies in New York State achieve $245 million in economic impact and helped create and retain 382 jobs over the past decade through industry research collaborations.

Collaboration

CAMP is a collaborative resource partner with the ability to work cooperatively with other New York State CATs and Centers of Excellence to provide solutions for industry needs.