Facilities & Instrumentation

CAMP's instrumental facilities are established to address the many characterization needs of research projects happening across Clarkson University's Campus and New York State businesses. With a focus on material properties, CAMP specializes in microscopy (SEM, TEM, AFM), microanalysis (EDS, XRF, XRD), and thermal analytics (DMA, TGA, DSC), and mechanical properties through the newly installed Aerospace Testing and Life Assessment Systems (ATLAS) Laboratory.

Many of these high-end tools are fitted with peripheral attachments to perform measurements under different environments with the capability to control atmosphere and temperature. By leveraging faculty demand the CAMP is constantly changing and upgrading instrumentation to better refine the characterization technologies being offered. Thorough training, analytical expertise, and our knowledgeable technical staff provide analytical solutions to a wide range of material-related problems.

Clarkson faculty and staff can book instruments through the EMS system. Potential non-Clarkson users should contact the CAMP office.

Instruments Managed by CAMP

The new Aerospace Testing and Life Assessment Systems (ATLAS) Laboratory is a cutting-edge, multi-user research facility for testing materials under extreme environmental conditions, from -150°C to 1200°C. The facility was established through a $1.4M grant from the Office of Naval Research, making it unique in the country.

The ATLAS lab is equipped with five advanced ZwickRoell test frames for faculty and students to study and develop models of material behavior and testing for extreme environments, including fatigue, creep, and failure tests on metallic, composite, and polymer materials for industries like aerospace, maritime, and space exploration.

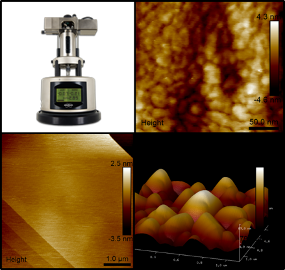

This recent addition to the CAMP suite of instruments is a well-known workhorse in the AFM field. The MM8 is capable of acquiring high resolution images in a relatively short amount of time and is equipped with Bruker's automated ScanAsyst mode allowing for self-optimizing images if so desired. When choosing more typical imaging modes such as Contact/Non-contact the instrument can simultaneously report multiple data channels. Commonly selected channels are height, phase, modulus, and friction. This tool is able to handle a wide range of samples types such as thin films, composite surfaces, biological specimens, and other fine materials like particles or proteins. Bruker's NanoScope Analysis software is loaded with many powerful analytical tools which can be used to perform measurements like roughness, 3D surface rendering, step size, and many more.

CAMP's particular unit is equipped with a few modules that can be used to provide better control over your analytical environment. The liquid cell allows for the measurements in fluids, suitable for materials which need a hydrated environment or to observe the effect of moisture on your sample. The temperature controlling stage lets you ramp temperature up to 250˚C with precise control within 1 degree making temperature controlled changes in structure readily accessible. An environmental chamber can be used to control the atmosphere in the AFM and can be fit with a purge gas of your choice to observe the effects of atmosphere or measure under inert conditions. Bruker offers over 15 other optional imaging modes for this tool which can be purchased as an upgrade including nano-electrical and nano-magnetic measurements. With the current add ons and the highly modular capabilities this tool is well equipped to handle the AFM research needs of Clarkson University materials research for years to come.

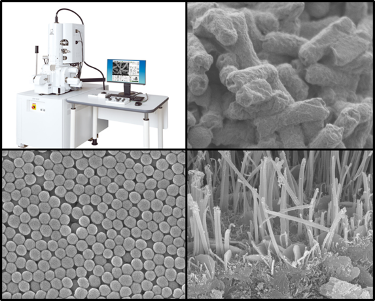

Recently purchased, the JEOL JSM 7900F-LV is a direct upgrade to the current 7400F FE-SEM which has served Clarkson researchers for the past 18 years. This new model not only boasts a better resolution, taking the previous 1.5nm up to 1nm and pushing 0.6nm at high kVs. This microscope is also equipped with a low vacuum chamber in order to better accommodate biological or other partially hydrated specimens. While many of the familiar capabilities are available such as Secondary Electron Imaging, Low Energy Electrons, Beam Deceleration, and Backscatter Electron Imaging, this SEM is capable of not only pushing the resolution but also providing high quality images at low accelerating voltages down to a few 10's-100's of volts, a regime previously rendered problematic due to high noise. All of this next-generation performance is also backed up with an easy to use software interface, increasing the ease of use for those new to SEM, while still providing full manual control over analytical parameters for the experienced microscopist.

A set of peripherals from Oxford Instruments take this microscope from just an imaging machine to one that is also capable of simultaneously collecting EDS and EBSD. The Aztek Ultimate EDS detector is a Silicon Drift Detector, a newer technology compared to the older Si-Li crystal of our older model, this allows for much faster measurements, in many cases measurements that used to take 30 minutes can now be done in 5 or less under the proper conditions. With this system it will be possible to collect elemental information at times nearly as rapid is collecting an image. The analytical package includes functionalities such as live x-ray mapping, quantitative analysis, drift detection, and large area mapping where multiple images can be stitched together. The EBSD system can be used to detect the distribution and orientation of different crystallites on the surface of a material and index the phase data, correlated to an image. With this combination it is possible to simultaneously learn about the morphology, elemental distribution, and crystallographic information of a well prepared material.

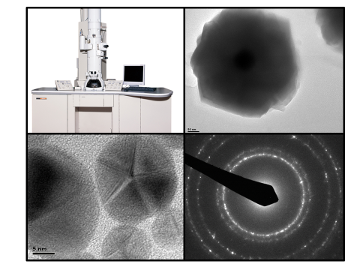

This high resolution transmission electron microscope is a workhorse of the microscopy world offering a good selection of imaging modes and range of magnifications. Capable of bright field, dark field, and diffraction imaging this microscope can reach an ultimate resolution of 1.4 Å under diffraction contrast and a magnification of up to 1.5 million. Powered by a Gatan CCD camera digital images can be collected in seconds and microscope alignments are retained when changing magnification or switching from imaging to diffraction modes resulting in minimal time between images. A fantastic choice for characterizing a wide range of fine features, this microscope readily characterizes fine powders, thin films, biomolecules, composite materials, and many other forms of nanoscale features. Nanoparticles can be analyzed for size, shape, nano-sized features, and crystallographic information like phase and relative abundance of certain growth directions direction. Structural features such as core-shell, janus, or organic coatings can be well resolved with this microscope where other microscopic techniques may struggle. Thin layers of composite materials can be analyzed for crystallographic orientation at boundaries to determine how structural components are affected or how grain distribution contributes to other physical characteristics. CAMP's technical knowledge is always available to discuss how the TEM can be used to solve your research problems.

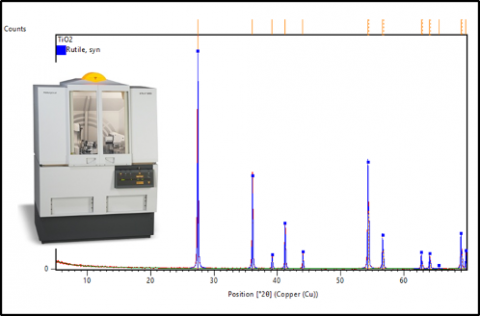

This high resolution x-ray diffractometer is an ideal selection when investigating the crystal structures of both organic and inorganic materials. Equipped with an analytical range of 0-175 ˚2Θ and a 0.001 ˚ step size resolution. The tool is equipped with programmable incident and receiving slits allowing for resolving reflections with even small differences in spacing in the case of complex mixtures. It is also appropriate for quick screening of the crystallinity of materials where well performing samples can be analyzed under more stringent conditions to get a high resolution diffractogram. The analytical software allows for not only plotting of data but can also be used to perform phase matching and determine the identity of unknown structures in your sample, both as the main component or as residual contaminants within the sample. Under the hands of a skilled crystallographer the machine can also be used to perform Rietveld Refinements to discover crystallite properties such as phase fractions of mixtures, grain size, micro-strain, and crystal structure solutions. Some specialized sample holders allow for the tool to handle irregularly shaped bulk samples, films, and even particles embedded in filters.

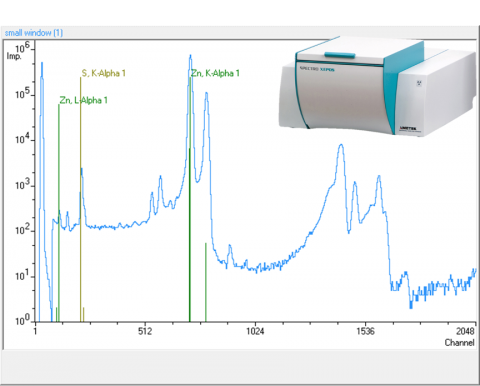

In applications where material must be routinely detected to a high standard of precision and accuracy, XRF measurements stand above other desktop compositional spectrographic techniques. With a limit of detection in the ppm range, this tool is well suited for trace analysis, detecting small differences in composition, and quality control screening for process development. Designed to handle a multitude of samples, the auto sampling stage is equipped to handle solids, liquids, and powders. Due to this precision and versatility XRF can be a superior choice over techniques like EDS for many bulk analyses where global sample information is more necessary and sample prep can alter the results.

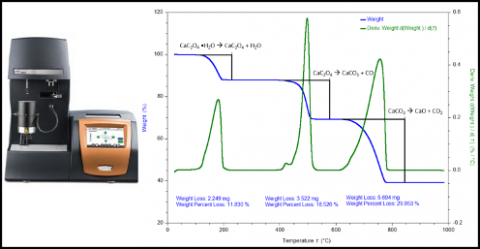

This new TGA from TA Instruments is a recent addition to the BMCL as an upgrade from the previous analyzer. The precision furnace allows good control over the sample atmosphere from room temperature to 1000 ˚C and can handle a good sample mass from a few milligrams up to a couple tenths of a gram. A noise floor of a few nanograms allows for the resolution of small changes in mass if only small amounts of sample are available. The furnace is also fitted with multiple gasses to allow for analysis under inert or typical atmospheric conditions, with other gasses available on-demand. With a dynamic environmental control decomposition or combustion can readily be analyzed. Among those isothermal decomposition, thermal stability, and outgassing can be closely monitored for a wide range of materials.

DSC is a laboratory staple for those trying to understand the thermal behavior of their materials. This particular piece of instrumentation provides information on the phase behavior of materials through determining the differential heat against an internal reference. Used oftentimes to study exothermic or endothermic processes, it is capable of capturing thermal events such as melting temperature, glass transition, thermal stability, cure onset, crystallization, and more. An external chiller unit allows the DSC to reach an analytical range of -150 to 725 °C. It is also possible to run a series of programs under variable atmosphere to determine how a material behaves in inert conditions as compared to air. This tool is a great companion to the DMA and DSC in order to have a deeper understanding of how a material responds under different thermal loads, or as a standalone measurement to determine fundamental phase behaviors.

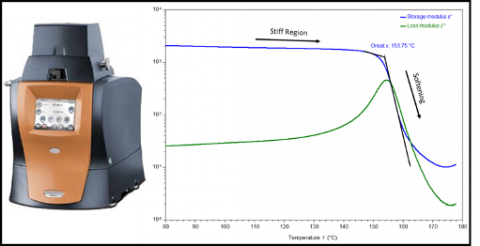

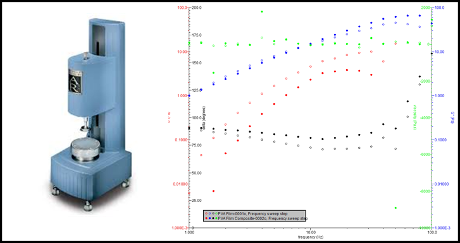

One of the most versatile thermal characterization instruments available, the DMA uses a frictionless air bearing to determine the viscoelastic response of solid materials in order to determine modulus data. The high precision furnace can be used across a temperature range of -150 to 600 ˚C with a tolerance of 1 ˚. With an analytical range of 18 N to 10 nN and a 1 nm strain resolution it can handle things from hard polymers and elastomers to soft materials and semi solid gels. Armed with a modular analytical space to handle different types of geometries such as bars, fibers, and films it can measure samples in the form of their intended application, there are also a selection of submersible clamps which can measure the effect of fluid baths on your sample. The programmable software package allows for a high degree of control which can perform measurements such as temperature ramps for storage or loss modulus, creep compliance, relaxation, stress/strain, or thermal response under custom temperature, force, and frequency conditions. The information available from the DMA also complements other thermal equipment in the BMCL such as the TGA and DSC.

The TA Instruments AR 2000 Rheometer is a great tool for analyzing the flow behavior of fluids, colloidal suspensions, and more viscous materials such as gels and pastes. Fitted with a high precision rotating head it's capable of sensing small changes in viscous response down to 0.1 µN·m on a temperature controlled stage that can heat up to 200 ˚C. A reliable tool for measuring viscosity, elasticity, yield stress, and shear thinking/thickening it can be programmed for a multitude and analysis types. Common uses of the rheometer include stress relaxation, creep ringing, creep recovery, and oscillation stress among many other routine measurements. This tool is a good companion to TGA and DSC measurements where physical changes can be correlated to thermally controlled behavior such as investigating glass transition states, melting points, or cure rates at varying temperatures.

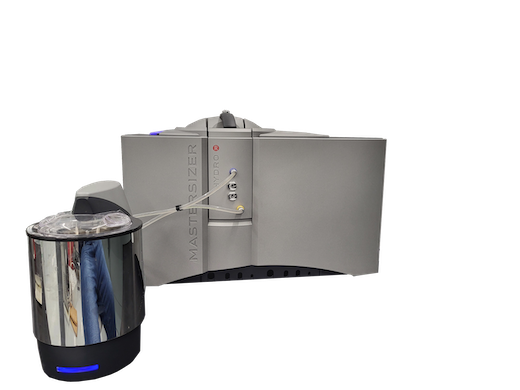

A great selection for analyzing particle size distributions, the Malvern Laser Diffraction Particle Sizer is equipped with an overhead stirrer and ultra-sonicator to control particle agglomeration in solution. Acquisition parameters are programmable so that you can select a snapshot of your sample or perform a measurement at regular intervals to study particle aggregation in-situ. A dynamic size range of 50 nm to ~1 mm allows for the analysis of a wide range of sizes and distributions, a key capability for fine particle process and quality control.

In contrast, the Malvern Zeta Sizer is a Dynamic Light Scattering particle sizer which uses Brownian motion to calculate particle size, with a complimentary range of 1 nm to 2 μm this unit excels at measuring the hydrodynamic radius of dilute solution of small particles. Equipped with a zeta potential attachment, it can also be used to determine the average surface charge of particles in solution. The unit also has access to a high concentration module for when you are working with materials that are highly sensitive to the solutions they are dispersed in. These two instruments cover a wide array of particle types.

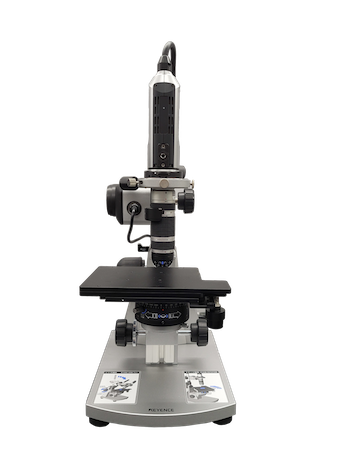

The Keyence VHX 970 optical microscope is a general purpose reflectance microscope which excels at analyzing the surface features of materials. With a 20-200x zoom, directional light source, and on-board image optimization features, it can handle almost any sample for surface analysis.

It takes advantage of the motorized stage in order to extrapolate 3-D surface maps, allowing for investigation of tolerances, crack propagation/initiation, and defects. The articulated tilting functions also allows for high resolution imaging up to 90 degrees, opening up the capability of stereoscopic imaging and contact angle measurements.

Available Instruments Managed by Other Faculty/Departments

- Single Crystal X-ray Diffractometer

- Nuclear Magnetic Resonance (NMR) Spectrometer

- Raman Spectrometer/Microscope

- Nanoindentor